Thank you for purchasing a ScreenHouse

DIY Porch and Patio Screen Wall Kit

Your purchase is designed and engineered by more than 20 years of commercial and residential design and proudly manufactured in the USA from responsibly sourced materials in the state of the art manufacturing facilities at Superior Mason and Four Seasons Building Products.

Your purchase is covered by the best warranty in the business with a limited 15 years warranty on the insulated panels and a limited lifetime warranty on all the aluminum extrusions.

DISCLAIMER**

This document is intended as a guide only. There are far too many variables within existing structures for us to address each an every one. As such, this kit is very adaptable and nearly any error is easily corrected within the existing materials received. Assembling this materials supplied kit will require patience & common sense. If you have any doubts about the action you should take we are just a call or email away for support. A reference cut sheet, 3D model and various drawings (plan view, roof view, elevation view, etc) are available in the customer portal or by request. We will not be responsible for errors in cuts made to the material.

PLEASE READ AND REVIEW COMPLETE INSTALLATION GUIDE STEP-BY-STEP

Installation Basics

The Screen House Insulated top screened enclosure installation guide recommends 1-to-3 physically fit individual(s) with some experience in Do-it-Yourself (DIY) home projects and should complete installation within 1-2 days depending on the size and with proper planning.

Please review this installation guide thoroughly and understand each step’s task before the start of the installation process. All recommended tools are required for a successful installation and some components will require alterations to fit your structure’s unique installation. This installation guide is intended to be reviewed along with the custom layout for the room to be installed provided with your quote.

NOTE: There are several different configurations and installation methods. This guide is for a porch screening kit using the 2x3 screen system This is based on a walls only installation with a roof already in place. If the supplied quote with your custom layout uses the standard 2" wall system or you have full enclosure with roof, please refer to the correct installation manual for this type.

Inspect your project area for safety issues noting all electrical power lines and electrical outlets.

DO NOT begin this project until project area is safe.

Tools You Need

Recommend and required tools are not included but necessary for a successful installation of this enclosure. Each structure and location is unique, so please review along with custom quote layout and call our team for support with any questions at 1.800.922.4760.

- 1-2 friends

- 4 ft. Carpenter’s level

- Carpenters square

- Chalk line (to mark “U” channel locations)

- Cordless drill/nut driver

- Caulking gun

- Chop saw with a metal cutting blade on it (required to make accurate and precision cuts)

- Ladders

- Masonry bits for drilling into concrete; masonry fasteners (if necessary)

- Metal file (to smooth cut edges)

- Hammer, Screwdrivers, Drill, tape measure, Box knife, Gloves, Safety eyewear

Materials

Inventory all materials received in your shipment within a safe distance from the work area before you begin the installation process. Each step in this process will note components used to complete the task on each page. As these rooms are very custom, not all items below will be included with every order; however, a room specific materials list and cut sheet are available through the customer portal or on request by email.

Note: While every effort is made to keep this up to date, individual items may be replaced with equivalent new versions of the material at the discretion of the manufacturer and may not match up with items below. Please call or email our support team and we will review and provide guidance on the installation of the new material options. A "*" in the part number list below represents a designation for the color.

**Items labeled as "Special Car Wash" or "Custom Walk Cover" on the BOL you will receive with the delivery are generic catchall line items from the manufacturer. These are not items you will receive, only a label from the manufacturer for the custom bundle that follow below it**

Screen Wall Extrusions

| Part Number | Part Description | Dimension | Image |

|---|---|---|---|

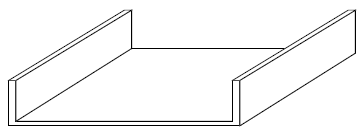

| 05263* | 0.68" x 3" Uchannel | .75" H x 3" W x 24' L |  |

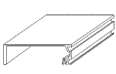

| 05268* | 1" x 3" mainframe | 1" H x 3" W x & 24' L |  |

| 05271* | 2" x 3" mainframe | 2" H x 3" W x 24' L |  |

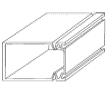

| 052734* | 3" x 3" Outside corner post (Standard) | 3" H x 3" W x 24' L |  |

| 052595* | 1.5" x 3" uchannel | 1.5" H x 3" W x 24' L |  |

| 052647* | 3" x 3" Multi-Corner (Spline grooves at 4 corners, no kickplate groove) | 3" H x 3" W x 24' L |  |

Screen Wall Components

| Part Number | Part Description | Dimension | Image |

|---|---|---|---|

| 11011* | 2" Mullion Clips (supplied on orders with a kickplate) | 1" x 1" x 2" |  |

| 11014* | 3" Mullion Clips | 1" x 1" x 3" |  |

| Varies by type | Screen roll | Width varies, 100' long |  |

| 25* | Series 2600 Screen Door (assembled or knockdown) | 36" or 32" W x 80" W (standard) |  |

| F250K* (18") 047475* (24") | Embossed Kickplate - 50' roll in most cases in an individual box | 18"H x 50'L 24"H x 50'L |  |

| 124-F | Flat Spline | .180" x 1500' |  |

| H310A0015 | Foam Tape | 1/2" W x 15' L |  |

| P860* | Touch up paint | NA |  |

| 819536* | Color matched tek screw | #8 x 3/4" (100 per pack) |  |

| T410 | Heavy Duty Screen Roller | NA |  |

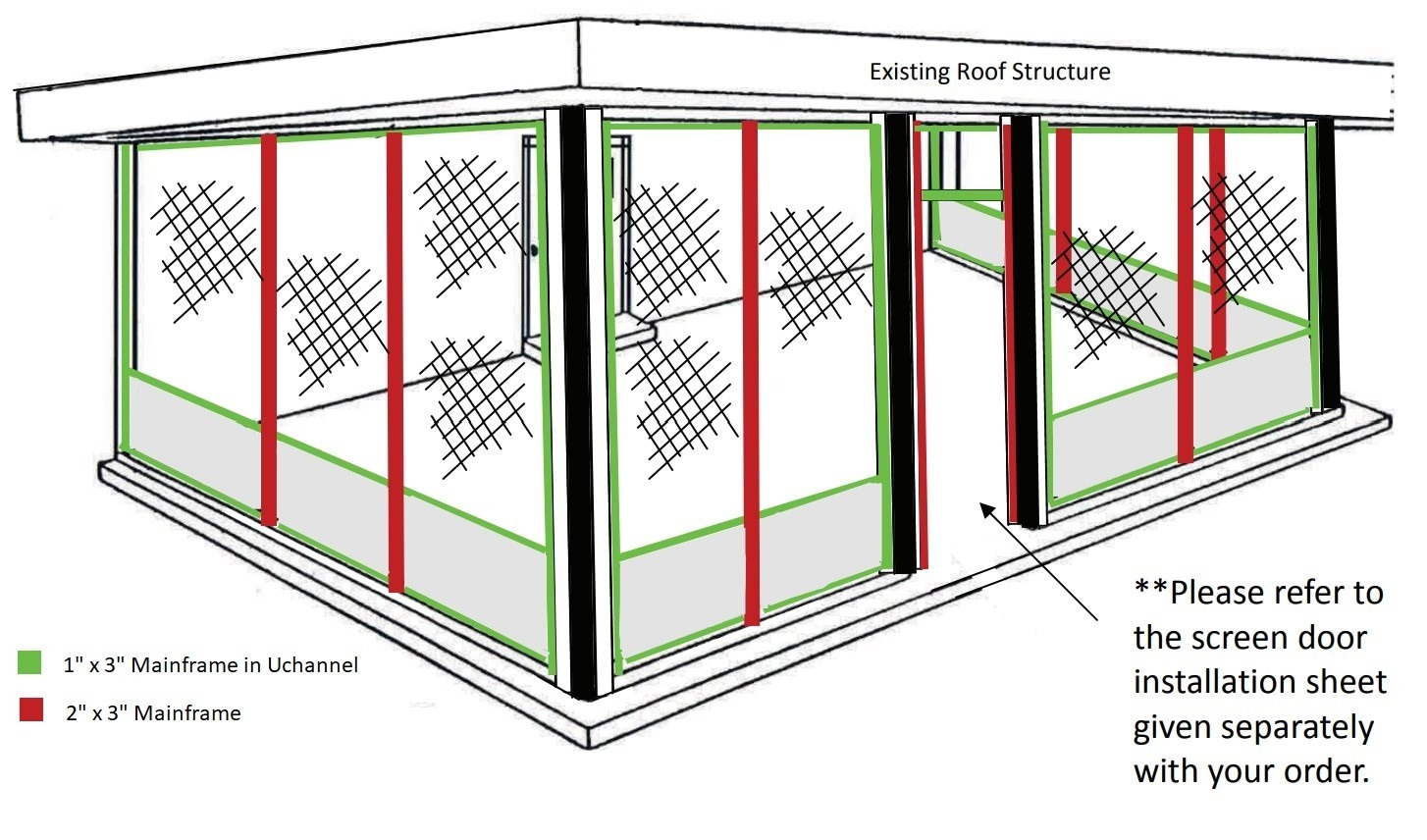

Screen Wall Kit Overview

In addition to the details on the following pages, there are a host of valuable resources available in the specific page in our customer portal for the quoted enclosure. You would have received access instructions by email when the order was placed. Please contact as customer service rep if you misplaced these instructions.

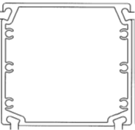

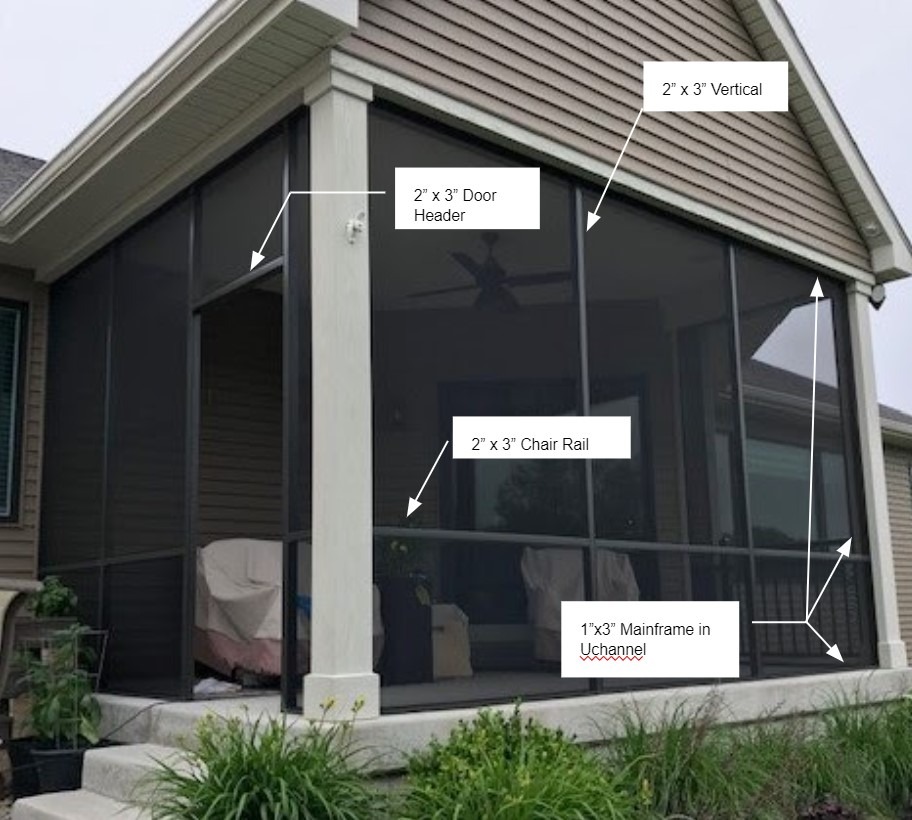

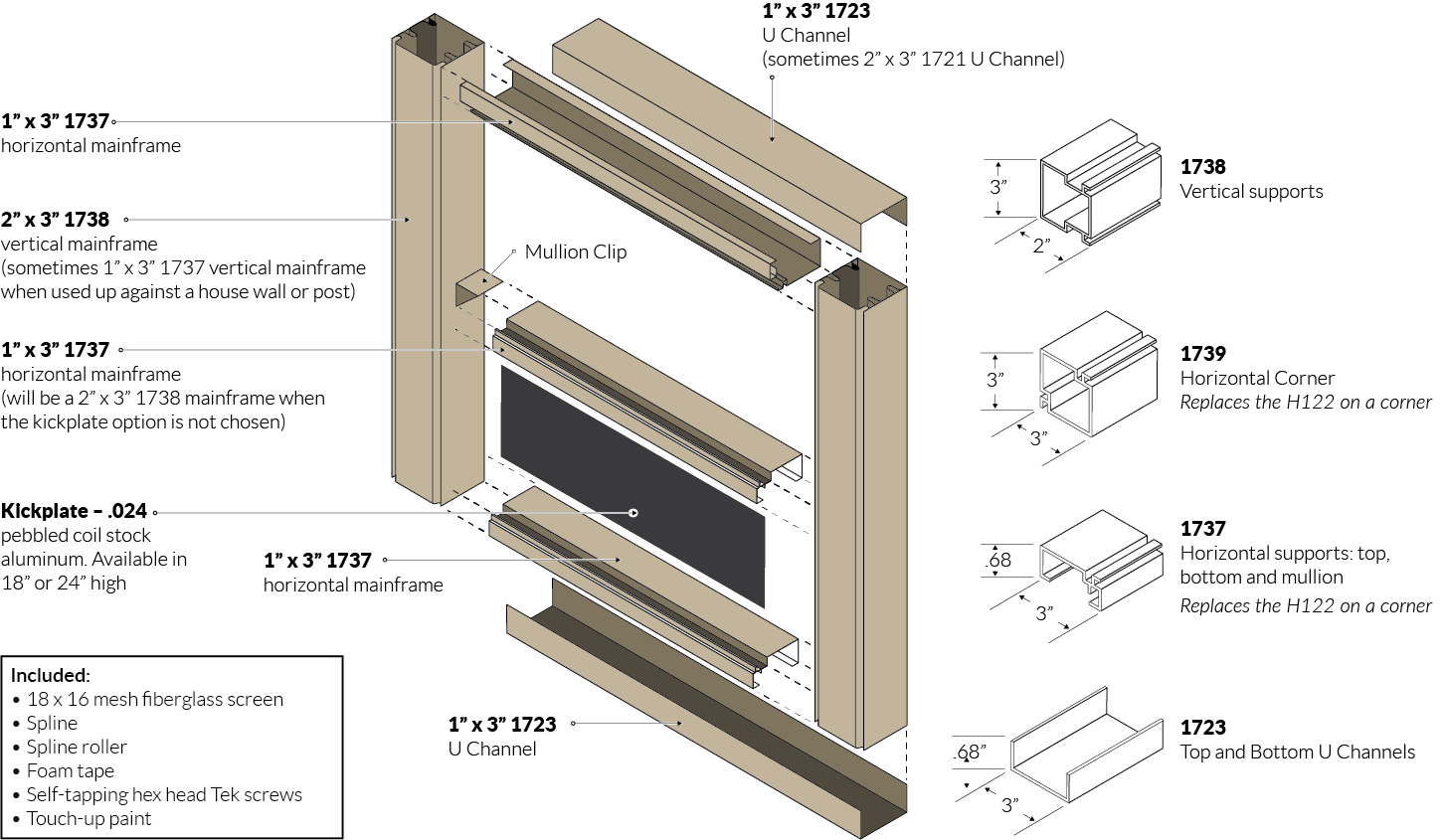

3" Screen Wall System Exploded Detail

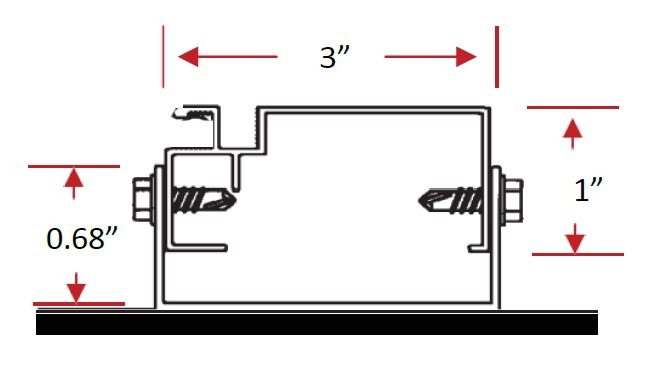

Step 1: Install Uchannel

Between the guidelines given below and the drawing you received with your quotation you should have everything you need to assemble your unit. If you need clarification on any point of the assembly we will be glad to help. Before cutting anything, please lay out the material you have been given and understand how each piece is to be cut and placed, so that you know you have enough material to do the job. Always call before cutting if you are in doubt about anything.

NOTE: When quoting a screen walls only system, we do our best to make the smartest use of materials in order to keep the pricing as reasonable as possible. Sometimes, the most efficient use of materials (due to the extrusions only being available in 16’ long and 20’ long standard lengths) will mean the end user will be required to butt splice certain screen enclosure profiles. Butt splicing will be the most common for top, bottom, and rear wall uchannels.

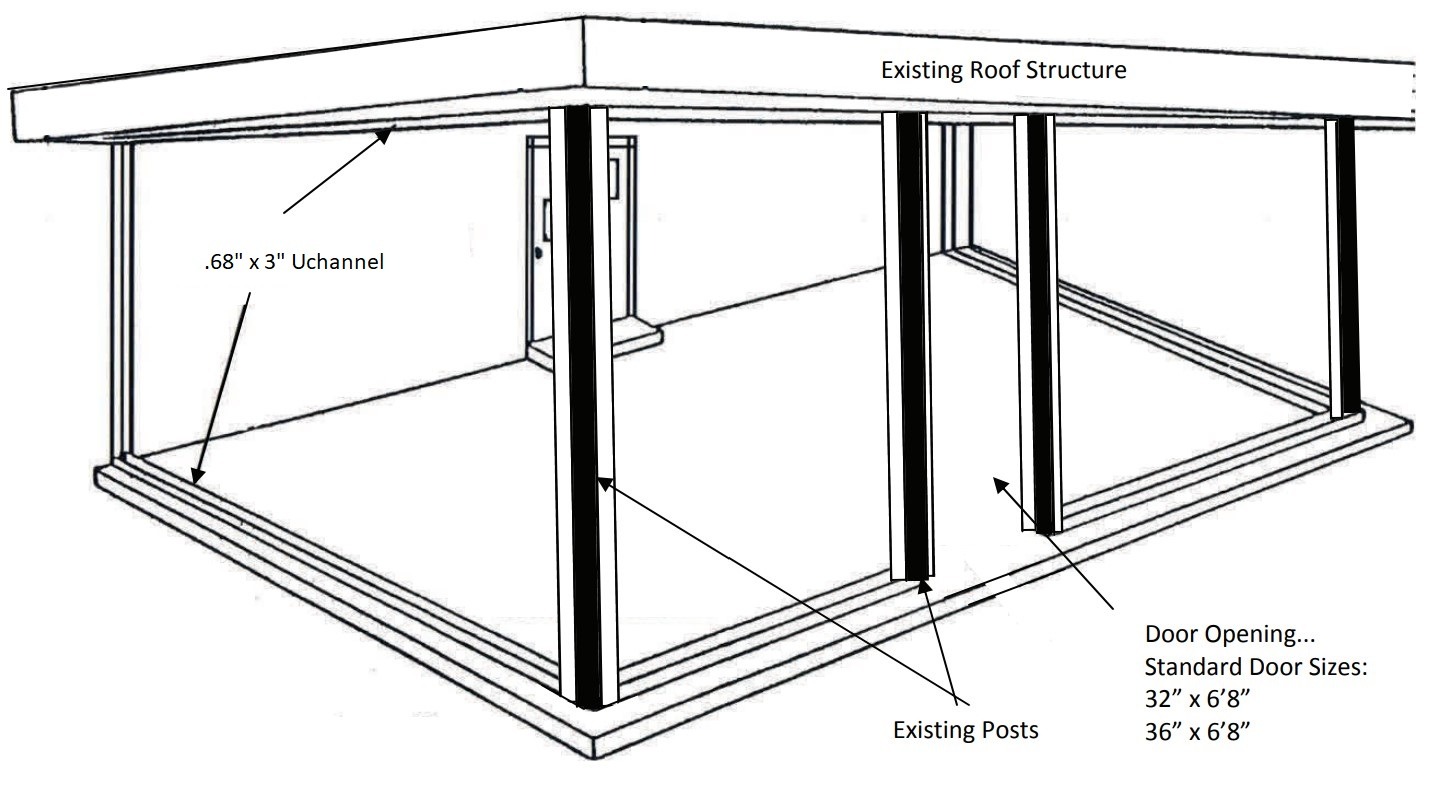

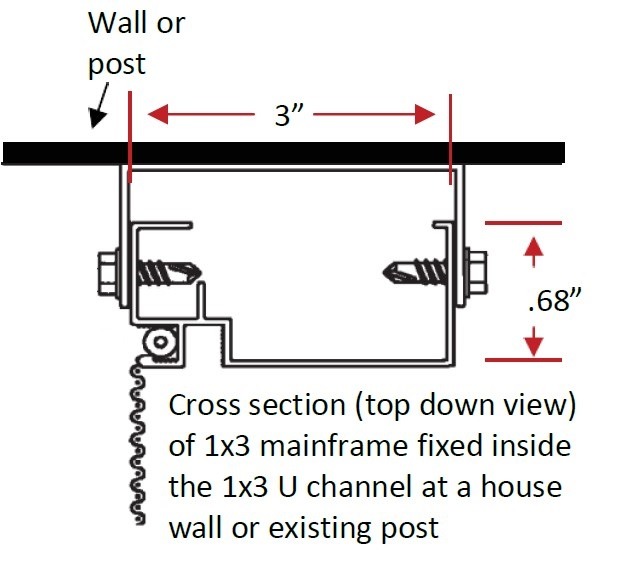

Uchannel is used to frame in all openings and offer a surface to secure the vertical posts and horizontal mainframe with spline grooves. It is mounted to the floor, the underside of your existing roofline and vertically up the house wall on each side of the room and any existing posts.

TIP: Uchannel is not run on the floor where a door is to be installed. In such cases, leave a 36" opening between uchannel for a 36" wide door (adjust based on actual door ordered with your kit).

You can choose to miter cut the Uchannels where they meet at the corners; however, the most common, and easiest, choice for installation is a square butt where they meet. For instance, install both top and bottom U channels in one length from house wall to the corner post and then vertical uchannel on house walls gets installed between the top & bottom uchannel installation. For standard outside screened openings, the horizonal uchannel is run the full width of each opening on top and bottom and then the vertical cut to fit between these on each side.

In your hardware box you will find a roll(s) of 3/4" X 3/4” foam tape. You may choose to use this on the back of the vertical U channel installations in the case of an uneven or rough vertical surface, such as brick or step siding.

Other Tips:

- If you are mounting the U channel to concrete or brick, we would suggest using either Tapcon screws or drive anchors to secure the U channel to those surfaces. For all wood surface installation you can punch or drill a starter hole in the aluminum and use an appropriate size wood screw to secured the U channel.

- Though it is not necessary, you can, in order to waterproof the seal between U channel and floor surface, apply a bead of high quality silicone to the underside of the U channel prior to securing it to the cement or wood surface. Alternatively, if you have a sloped pad and you would like to have some drainage, you can drill holes in the uchannel along the length for this purpose. Of course, this does provide an opening for bugs to enter potentially.

- We recommend using Tapcon anchors if securing the uchannel to concrete pad or brick surfaces. For wood or trex decking, drill a starter hole and use a galvanized or zinc deck screw to secure. This mounting hardware is not included in your kit.

We recommend spacing screws or fasteners every 18” to 24” depending on the total length of the installation

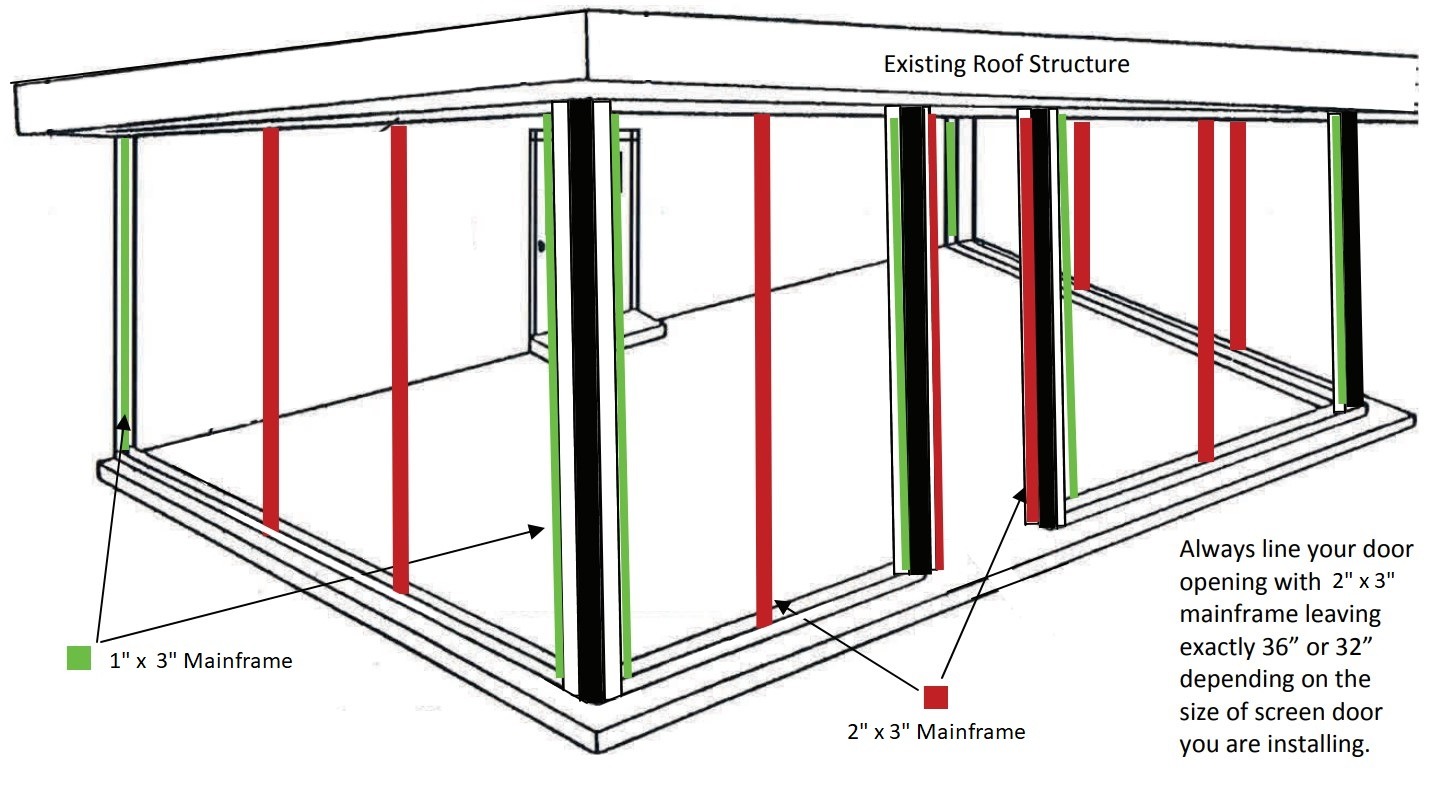

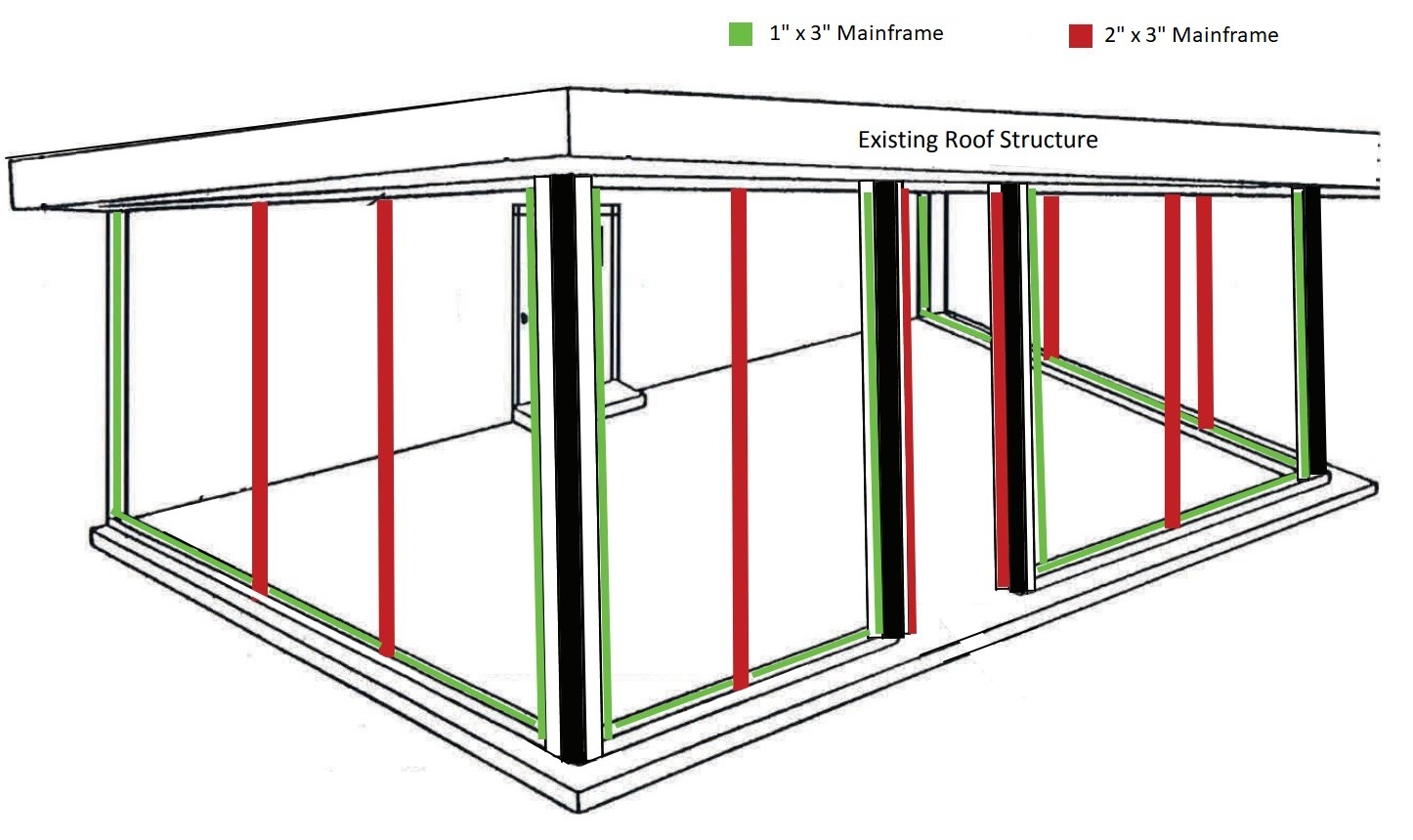

Step 2: Install 1x3 Vertical Mainframe

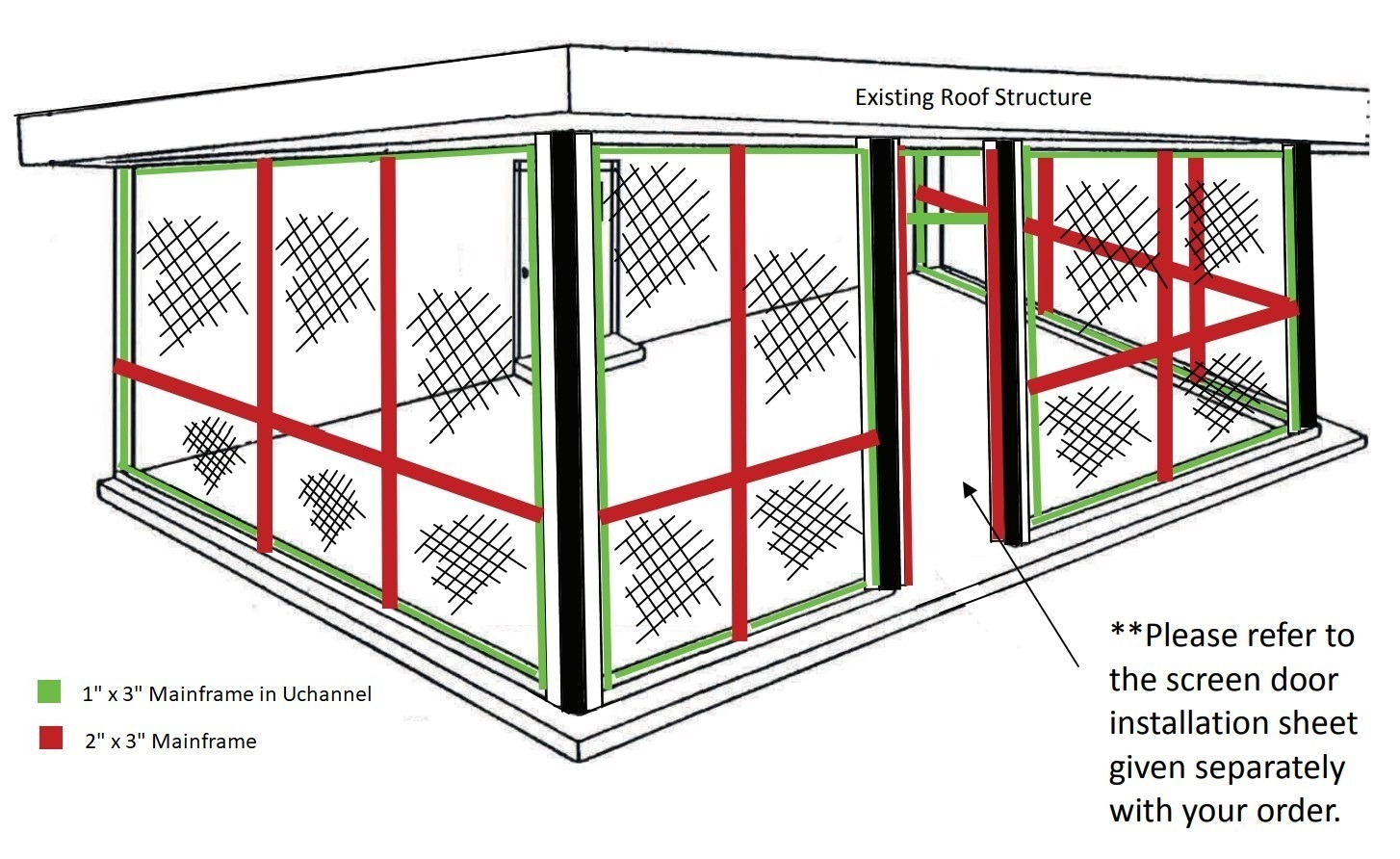

Now that uchannels are installed, its time to install all the vertical members and secure to this uchannel. Refer back to your custom layout drawing and identify all vertical 1x3s that will be installed to complete your room. Tip: The vertical members will be shown in GREEN on your custom room sketch.

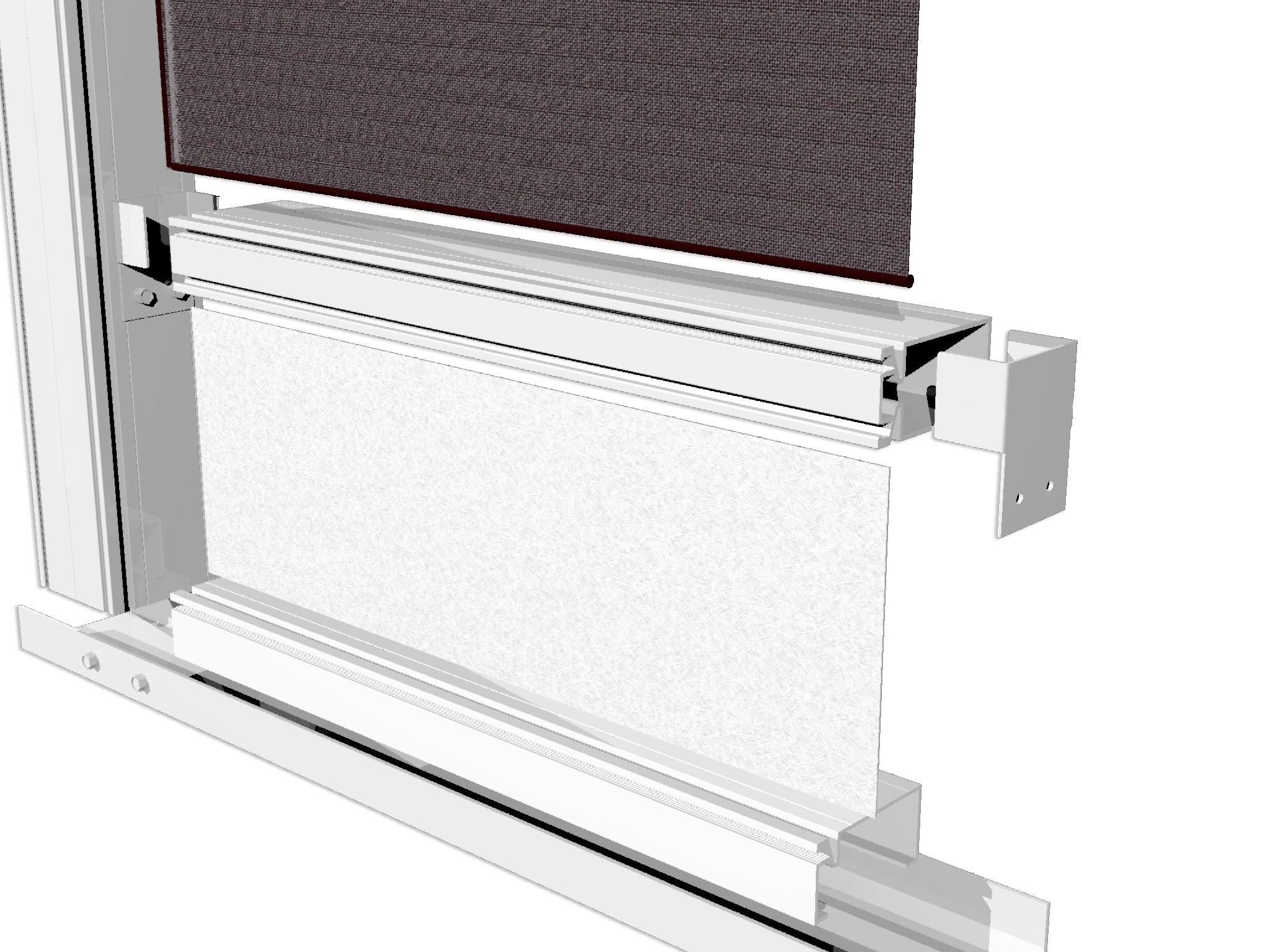

To start, cut and Install the 1" x 3" mainframe in the Uchannel previously installed on the house wall and up all existing posts. You will use the Uchannel as means of plumbing this mainframe. Secure the 1x3 mainframe into the U channel using the supplied self tapping hex head Tek screws. Secure the mainframe with the Tek screws on both sides at a rate of (4) Tek screws per 8 ft. length on each side. NOTE: If using the 1.5" x 3" uchannel, be sure not to place 1x3 mainframe all the way down into the Uchannel as you must leave the spline groove exposed for screening, as illustrated on the right. In most cases with the standard .068 x 3" uchannel, this is not an issue and the 1x3 mainframe sits at the bottom of the uchannel. |  |

Generally, 1x3 mainframe will be used up existing vertical house walls and existing posts (illustrated below in the ‘green lines' in Step 3); however, 2x3 mainframe can be used as well. It would be provided when a door is installed adjacent to the house wall (or on request) and would attached the same way as the 1x3 mainframe. Consult the drawings for your custom room to confirm which profile of mainframe is to be used against existing surfaces in your application.

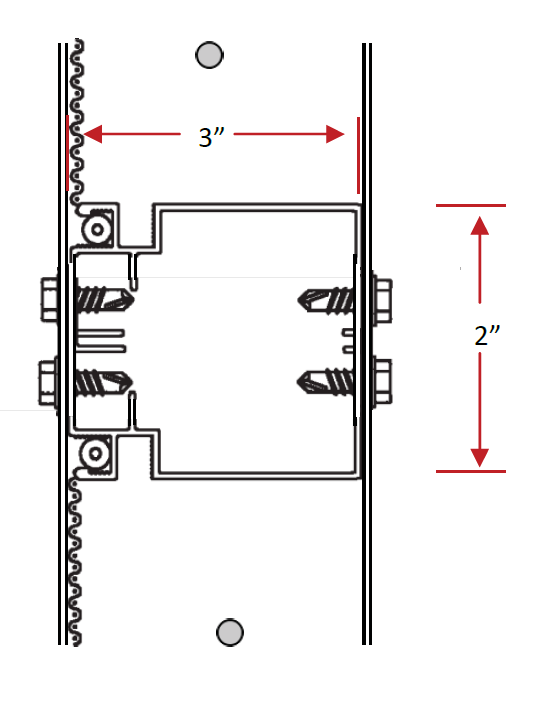

Step 3: Install Vertical 2x3 Mainframe

Next install the 2" x 3" vertical mainframes. These will be the RED indicators on your custom room layout sketch (and yellow in the case of corner posts). You will space them apart based on the spacing indicated in the drawing that came with your quotation prior to making your purchase. Please be sure to orient the spline grooves of the verticals properly to suit your installation with either outside or inside screening. The most common approach is outside screening, but if you are installing in a location with no access to screen from the outside, inside screening is also fine with this system.

NOTE: Spacing indicated in your drawing is post / house wall to centerline of 2” wide vertical and centerline of vertical to vertical. You do not have to worry about being precise with this cut (length of vertical) since any small indiscretion will be hidden inside the top and bottom U channel. Additionally the spacing between verticals is flexible ( 1/2” to 1”) as long as you do not exceed the width (.1”) of the screening provided

Secure the 2x3 mainframe in place, inside the top and bottom U channel, by using the self tapping hex head Tek screws. Secure both top and bottom and on both sides as illustrated on the right in the overhead cross section of a 2x3. Finally, install 2” x 3” mainframes on either side of door opening, making sure they are plumb and have enough space between to accommodate the door to be installed. For example, if you have a 36” door you will need a daylight opening between verticals of exactly 36" wide x 80" high. Install a 2” x 3” on either side, leaving exactly 36” for your door installation. Once again, refer to your drawing that came with your quotation, prior to purchase, to be sure of what you need to do for your application. |  |

The images below show correct installation of the 2x2 verticals with an outside screen application. This would be identical for the 3" wall system only with the additional depth dimension. The kickplate grooves on the inside face of the vertical and horizontal mainframe should always meet up as shown here.

2x2 Mainframe in Bottom Uchannel 2x2 Mainframe in Bottom Uchannel |  2x2 Mainframe in Top Uchannel ( with 1x2 installed) 2x2 Mainframe in Top Uchannel ( with 1x2 installed) |

TIPS:

- If you plan on putting your door in the first section against the house wall, or on a post the 2" X 3" will be used instead of 1" x 3" in the wall uchannel. This will be accounted for in your materials we have supplied.

- There is no bottom U channel nor 1” x 3” mainframe in door openings.

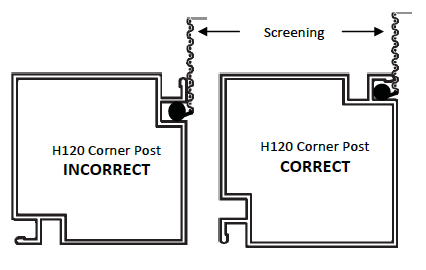

Step 3A: Install Corner Posts (option)

There will be applications that do not use existing posts for their screen wall installation (working inside or outside existing posts or railing, for instance). Move on to the next step if this does not apply to your room.

In such cases we supply 3” x 3" corner posts so that you can screen two walls that come together at 90 degrees. You will need to pay attention to the installation of the corner posts as they can be installed upside down, resulting in an improper screen and spline installation (the screen will pop out easily!)

| When installing the corners into the uchannel, be careful to verify the position of the spline groove is correct to screen each wall and not confused with the kickplate groove. The screen spline grooves should be on the outside face of the corner post on both the front wall and the side wall. If oriented properly, the kickplate groove will be on the inside face of the corner post in each direction (inside the uchannel). |  |

Step 4: Install Horizontal Mainframes

Depending on opening sizes and options select for your room during the quotation stage, there will be several different configurations, each with a slightly different final installation approach. Every installation will need to follow step 9A, but 9B and 9C will only be needed if you have chair rail and/or kickplate, respectively. Rooms with both a chair rail and a kickplate should follow all steps 9A through 9C.

Step 4A: Install 1x3 Mainframe in Uchannel

| Cut the 1" x 3" mainframes to fit between the vertical framing members and install in floor and roof channels using the self tapping hex head screws provided. Place at the proper level to keep spline groove exposed and then assemble with the self tapping hex head screws provided. Note: If your openings are not perfectly square (from slope of roof, for instance), you can lift one side of the mainframe out of the uchannel more than the other to square off the opening. This is beneficial if you plan to add 2 season windows in the future. |  |

If you do not have a chair rail, install 1 "x 3" mainframe as the door header, 80" from floor. If your unit will have a chair rail and or has a kickplate that uses a 2x3 mainframe over the top, install 2" X 3" as the door header. Again, the opening will need to be 80" from the floor to the underside of the door header.

For rooms with multiple chair rails, repeat the step above in each opening with the other chair rail(s).

Step 4B: Install Chair Rail

Rooms with openings larger than 42" and without a kickplate are recommended to have a chair rail for strength. The material used for the chair rail is the same 2x3 mainframe used for the vertical members.

Cut and install the 2" X 3" mainframe to fit between vertical mainframe you have installed in a previous step. You may install the horizontal chair rail at any height you wish unless local building code has a specific requirement. Otherwise, we would recommend sitting in your favorite outdoor chair, and install the 2” x 3” horizontal at a height that does not interfere with your sightline into your backyard.

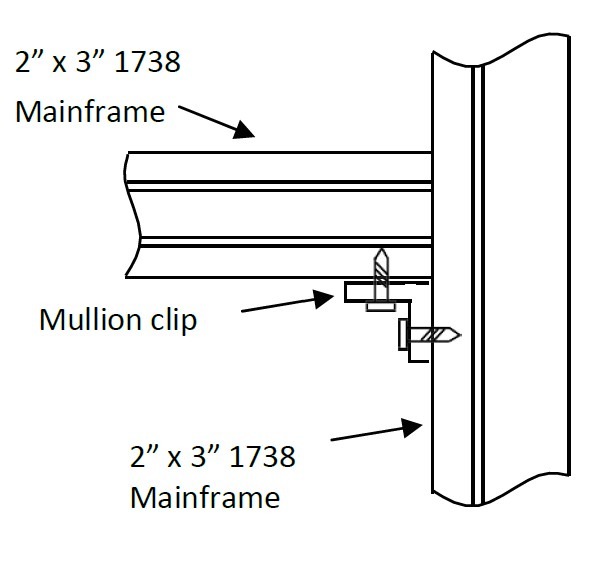

| Screw one of the mullion clips supplied in your kit to the 2" X 3" vertical at the desired height. Place your cut piece of 2" X 3" horizontally on top of this clip and screw the clip to the underside of the 2" X 3" on that one side. Then place a level on the 2" X3" horizontal before installing the mullion clip on the other side, to insure your mullion is level. Mullion clips should be color matched to your room. If unpainted version is sent, spray mullion clip with touch up paint (if desired) before installing screen mesh later in these instructions. |  |

The images below will show two views of an installed chair rail on a 2" system. The configuration for the 3" identical. The left shows a correct installation where the kickplate grooves of the material line up on the inside of the posts. On the right, the screen spline grooves similar align which is correct for an outside screen configuration.

2x2 Chair Rail Installed 2x2 Chair Rail Installed |  Front View of 2x2 Chair Rail Front View of 2x2 Chair Rail |

Step 4C: Install Kickplate (where applicable)

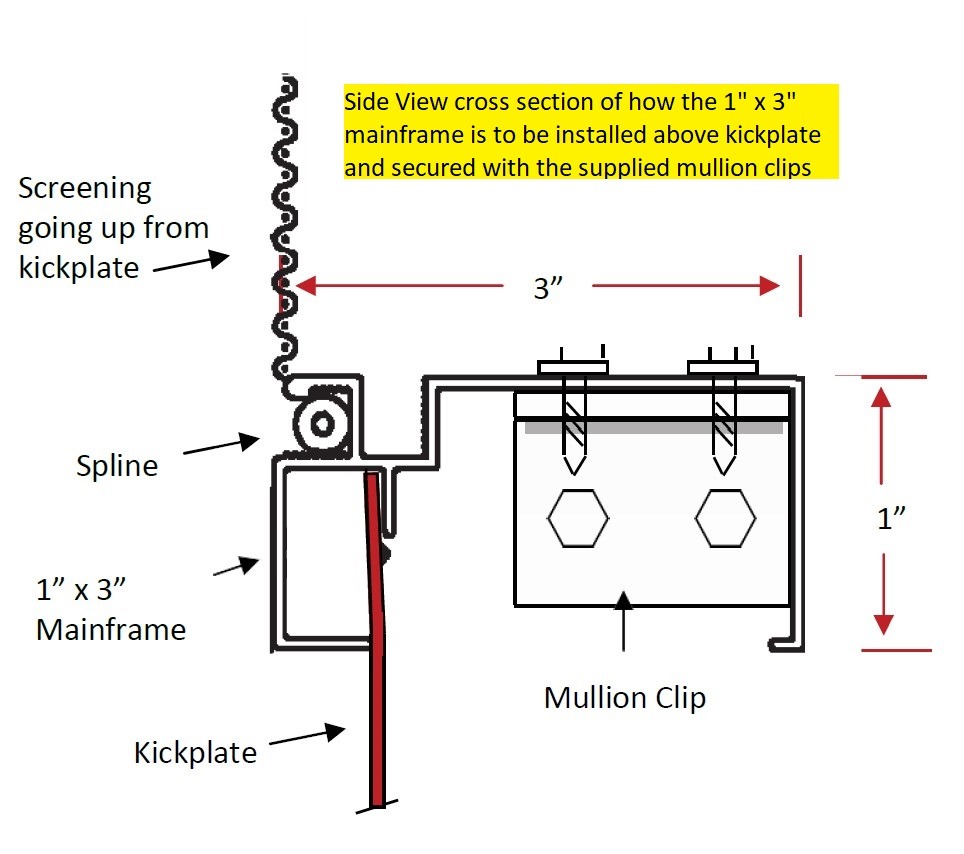

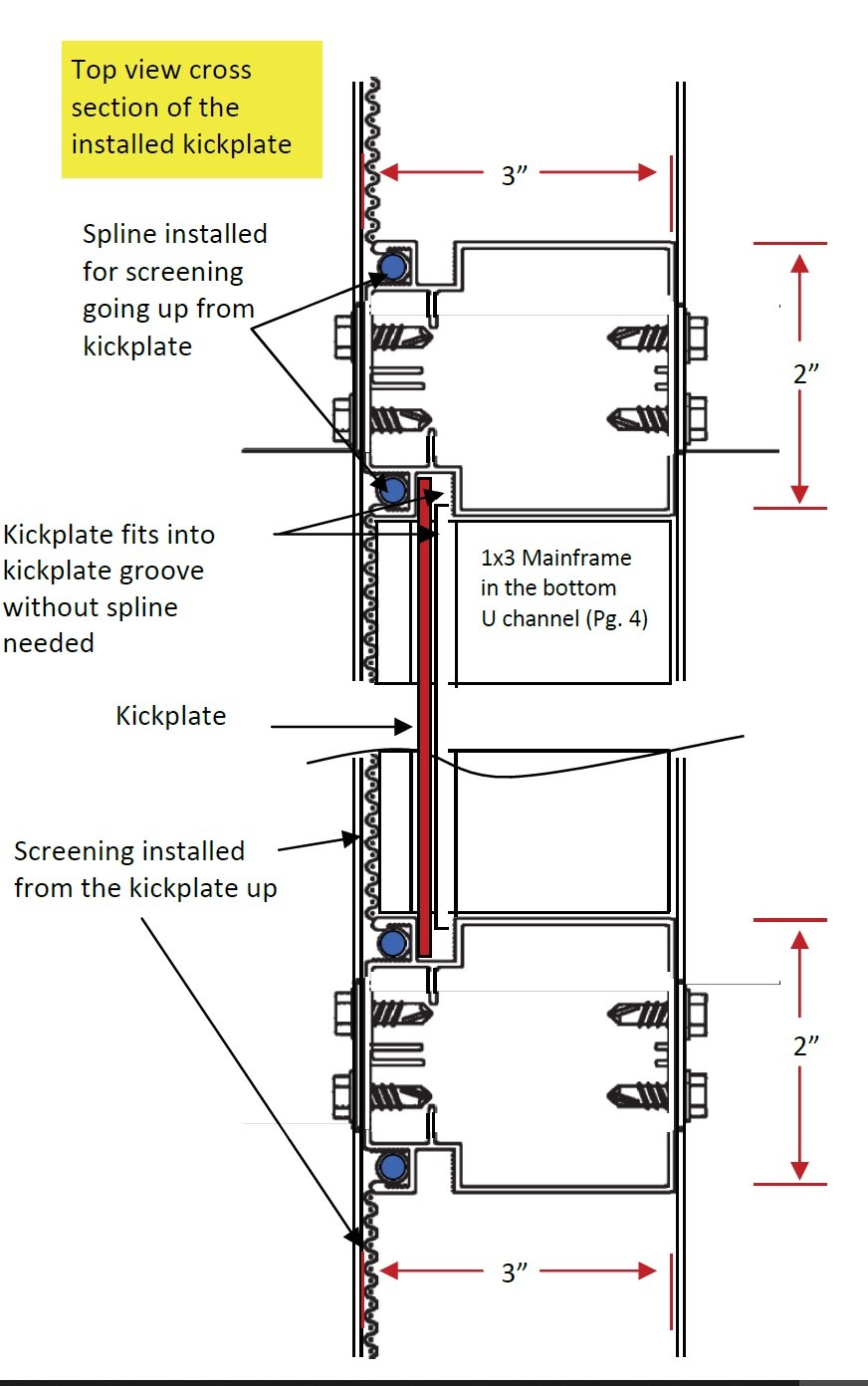

In general, kickplate is installed with 1x3 mainframe securing the kickplate which is shown in this section. For rooms that have openings greater than 54", 2x3 mainframe would be provided and would follow the same general process. Please refer to your room specific sketch provided with the order to determine whether 1x3 or 2x3 was quoted above your kickplate.

| Cut (or score and snap with a box knife) and install kickplate sections. Kickplate sections should be cut 3/8” to 3/4" longer than the opening width between vertical framing to account for the depth of the kickplate grooves. Slide the kickplate into place (see second illustration on the right). TIP: Kickplate is delivered as a coiled roll. Installation into the kickplate grooves is usually a bit easier if you cut and then allow each to flatten a bit before installing. Measure openings then cut and install the 1x3 (or 2x3) to fit between vertical framing members right above the kickplate. Temporarily set 1x3 mainframe over kickplate and make sure the kickplate slides completely into the designed groove (see the first illustration on the right). Once it is firmly seated, take a mullion clip and slide it up under the 1x3 mainframe where it meets each vertical framing member. With a pen, lightly mark the 2" X 3" vertical framing member where the clip ends with a line. Then remove the 1x3 mainframe and screw the mullion clips (one per side) to the vertical framing members using your mark as a guide for the bottom of the clip. As another reference, the top of the clip should be about 1/4” above the top of the kickplate. To accommodate the slope of the ceiling, floor or both, you must keep the top of the kick plates even from one opening to the next. You can use a string, running the full width of the opening, to accomplish this. The bottom of each kickplate section can be trimmed according to the slope of your application. |   |

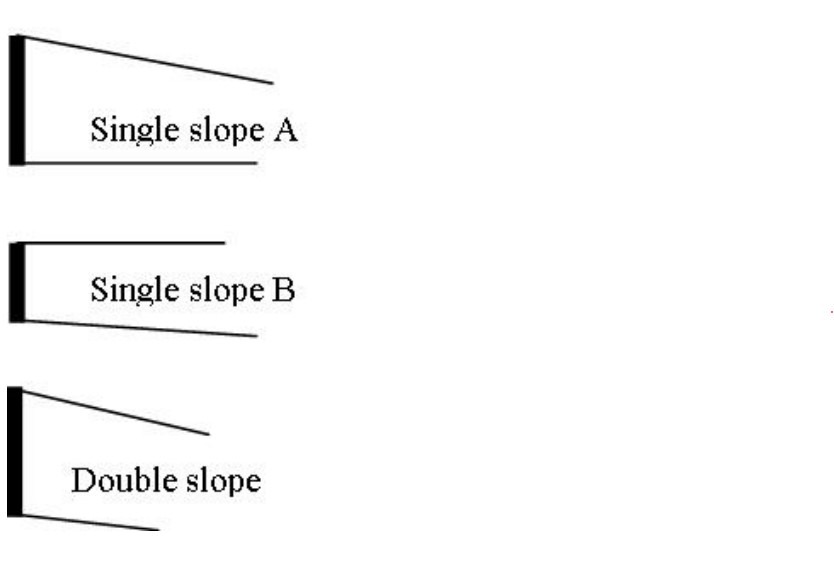

| Note: Be mindful of the ’slope’ of the 1x3 mainframe. Your existing construction will likely look like one of the 3 examples shown here. For example in the ‘single slope B’ scenario you will need to decide whether or not you will choose to run the 1x3 on top of the kickplate parallel with the slope of your existing deck or patio or with the existing roof line. |  |

Still using the ‘single slope B’ example above, if you install the 1x3 mainframe on top of the kickplate to run parallel to your roof line, your kickplate will get slightly larger on the “outside” vertical measurement, as you move away from the house wall to the front of your installation. The alternative is to run the kickplate perfectly parallel to the mounting surface (deck or patio) and the top screen section “outside” vertical measurement, will increase slightly as you move away from the house wall to the front of your installation.

Place the 1x3 mainframe on the mullion clips you have just installed and screw down (from the top of the extrusion) into the clips with the supplied self tapping hex head Tek screws.

NOTE: In cases where a room is ordered with double height kickplate, the above process is performed a 2nd time. to achieve the full height. The 1x3 mainframe will be installed above both the first and 2nd kickplate panels in each opening.

Step 5: Install Screening

Using the supplied screen, spline and spline roller, you will be screening in all openings generated through the construction of the room. If all steps above were complete properly, all openings show have spline grooves visible around the perimeter of the opening. If any opening is missing a spine groove, please review the appropriate section of the manual to correct.

If your room has no chair rail or just a kickplate, there will just be one opening per section to screen. For rooms with a chair rail, there will be a section below and another above the chair rail to screen in. The small opening above the door is also to be screened in.

We suggest rolling the spline and screening into the vertical spline grooves first, where the most tension on the screen will be at the midpoint of the vertical installation. Once you have both sides started you can have someone apply a light inward pressure with their hand on the screen as your roll the spline in. You can also try dragging the tip of your fore finger on the screening out in front of your spline as you roll to prevent the spline from pulling the material too tight.

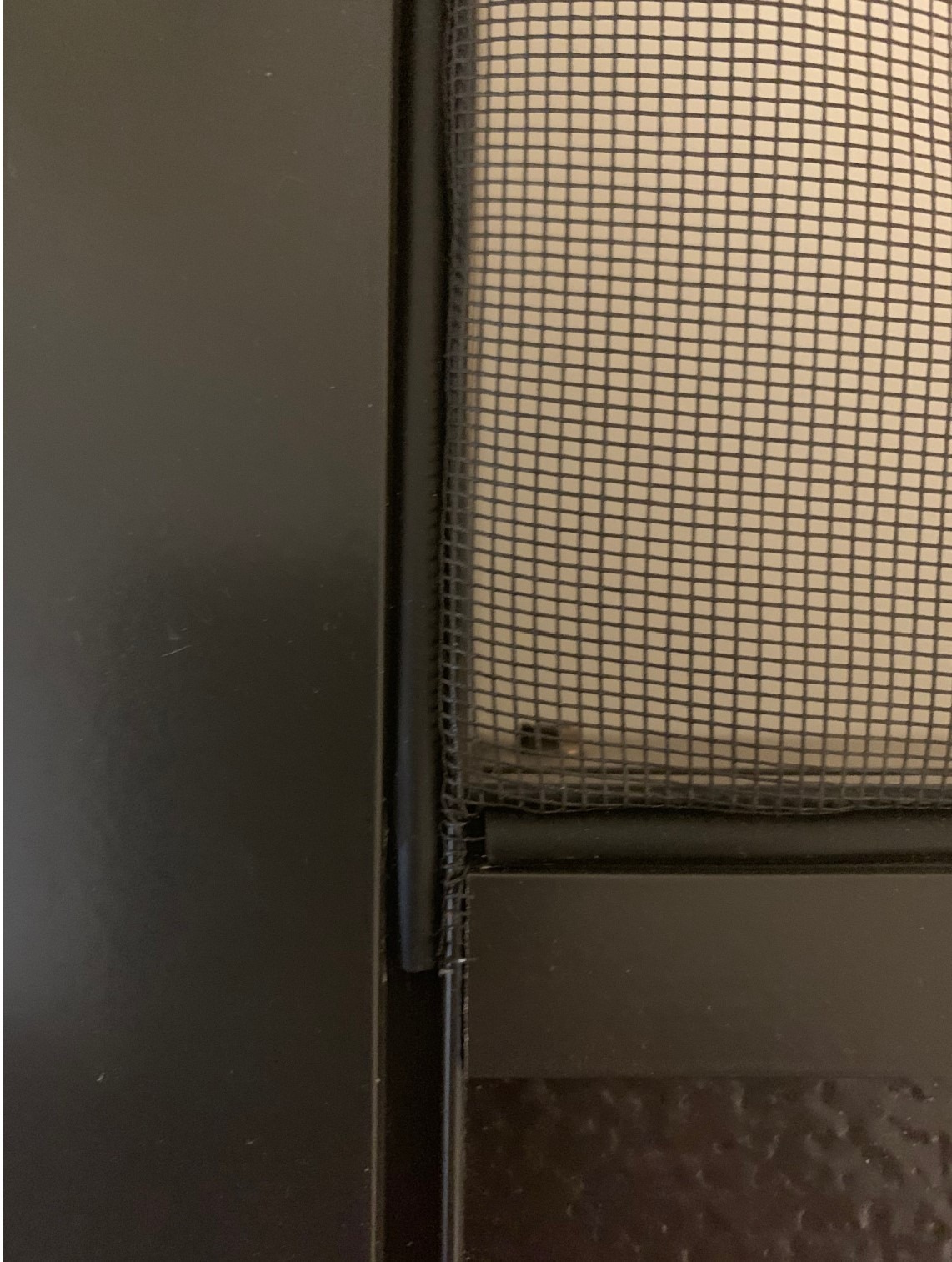

| Effectively, you are screening from side to side first, pulling the screen taught but not overly so. Then finish off the section by rolling the spline and screen into the horizontal spline grooves. You will use 4 pieces of spline per section rather than one continuous piece of spline. These pieces will butt against one enough, but will not touch as the horizontal and vertical spline grooves do not meet (see photo to the right). Trim off excess screening by running a sharp blade (razor or box knife) along the back edge of the spline. **You will need to take extra care not to pull the screen too tight on the up & down dimension. You may warp the horizontal center bar off ‘straight.’ |  |

TIPS:

|  |

CONGRATULATIONS! We hope you enjoy many years of maintenance free protection from bugs and the elements. If you have questions or need support at any time, please call us toll free at 1.800.922.4760.